Frequently asked questions about the Lead and Copper Rule Improvements

*The latest on LCRI administration challenges: In August 2025, EPA announced it will defend the Biden administration’s LCRI against AWWA’s lawsuit, while also “developing new tools and information to support practical implementation flexibilities and provide regulatory clarity.” This article explains what that could mean for your utility.

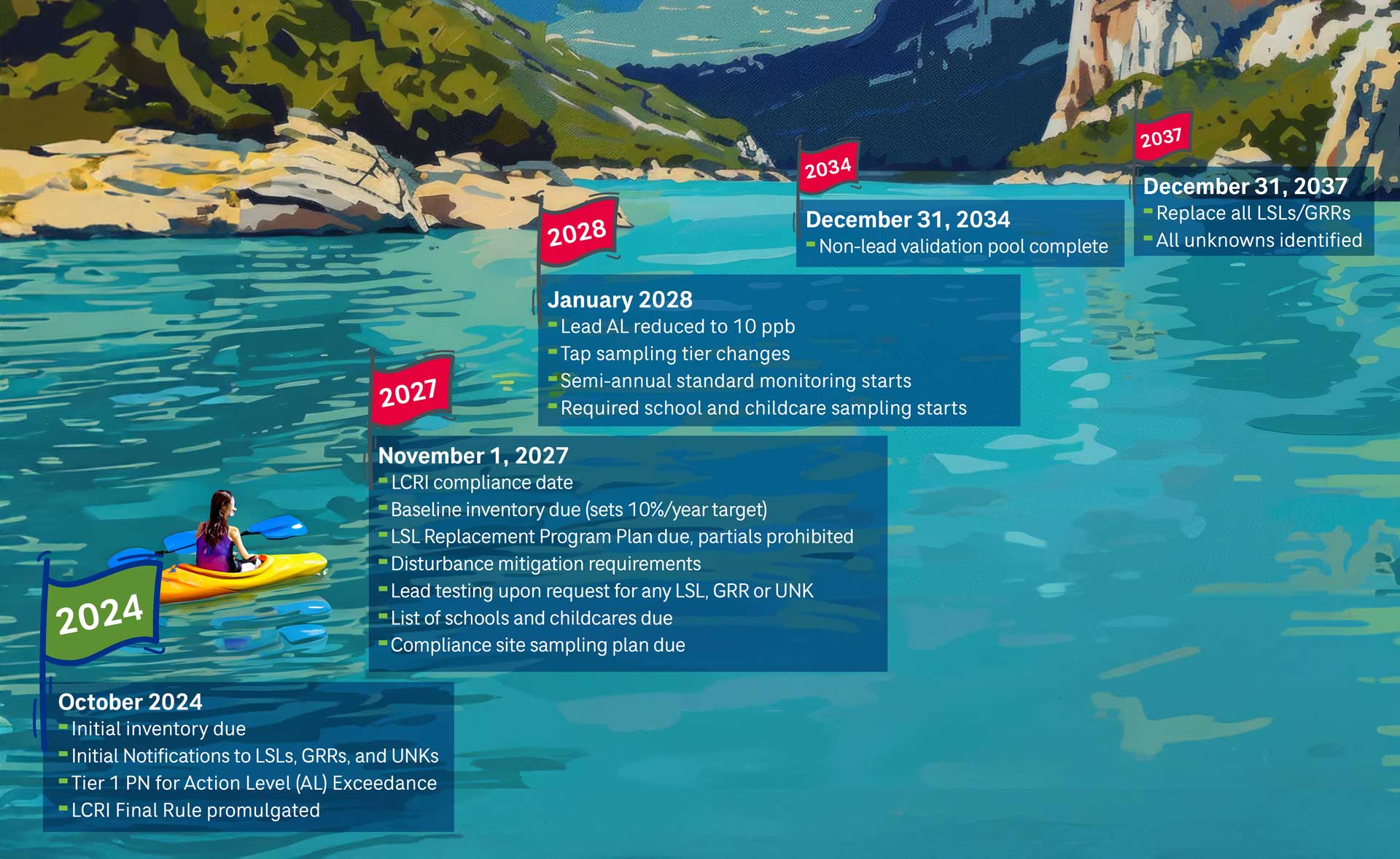

In October 2024, the EPA released the final LCRI to strengthen the Lead and Copper Rule Revisions (LCRR) promulgated in 2021. Most of the improvements go into effect November 1, 2027. In this article, our experts answer FAQs about the compliance timeline, partial and private side replacements, sampling protocols, corrosion control treatment, and service line verification and inventory.

What will be required of water systems that do not have any lead or galvanized requiring replacement (GRR) service lines?

Systems that do not have any lead or GRR service lines, but still have unknown materials in their inventory, will still need to comply with many activities. Those include annual notifications of unknown materials starting in 2024, submitting an annual inventory until there are no unknowns remaining beginning in 2027, developing a lead service line (LSL) replacement plan (in the event any LSLs/GRRs are found in the future), offering free sampling to unknown locations, performing school sampling, and participating in continued compliance sampling.

compliance timeline

What was due by October of 2024? With the LCRI promulgated, when is the next due date for related actions?

Initial inventories were due in October 2024, and utilities were required to send out notifications to consumers with service lines that are lead, GRR or unknown.

Public notification within 24 hours is also required for any action level exceedance when the 90th percentile is over 15 parts per billion (ppb) for the compliance pool (a “tier 1” notice) starting in October 2024.

Most of the LCRI requirements will go into effect in 2027. However, utilities must use LCRR health effects language on materials and provide annual notifications in line with the LCRR to consumers with lead, GRR, or unknown lines annually each November in 2025, 2026, and 2027.

The next major milestone is November 1, 2027 when the baseline inventory, lead service line replacement plan, list of schools and childcares and an updated sampling plan are due.

Does the LCRI supersede the LCRR entirely? What should water systems focus on implementing?

The LCRI supersedes almost all of the LCRR, with the exception of interim actions required between October 2024 and November 2027. Our experts’ recommendation is to focus on creating plans, procedures, materials, and workflows that comply with the LCRI.

Our team recommends refining the service line inventory by reducing unknowns and lead lines as much as possible before the “baseline” inventory deadline of November 1, 2027. This means moving forward with verifications and replacements. The composition of the 2027 baseline inventory will “lock-in” the minimum target metrics and schedules systems must meet to comply with the LCRI for the following 10 years.

Other recommendations for the pre-LCRI interim period include estimating your future 90th percentile under the new sampling site schemes and calculation methods now. Additionally, it’s key to determine what procedures and laws must be in place to begin work on private property, whether it’s material investigation or replacements. There are also some activities, such as school and childcare sampling, that can be conducted “early” while still counting towards compliance in the future. Systems may want to consider getting ahead on these future required schedules.

service line verification and inventory

A utility has replaced many lead goosenecks over the past 20 years but had no documentation of replacing them. Is that a problem?

Not really. The LCRI has a requirement for the baseline inventory to include information on the connector (i.e. goosenecks) for every service line location. The connector field for each corresponding service line must be classified as: lead, non-lead, unknown, or no connector present. If a utility does not have detailed location information for the past replacements, connectors can be classified as unknown. Importantly, under the LCRI, connector classification can remain unknown indefinitely without triggering replacement or notification requirements. Unlike with service line unknowns, there is no requirement to actively verify connectors under the LCRI—only when they are encountered during other activities.

What guidance has EPA released for the use of machine learning to identify lead service lines?

Although EPA has recognized the use of machine learning, it is ultimately the individual state’s decision on whether or not to approve it for assigning materials to service lines. Our experts suspect with the LCRI, that state regulatory agencies will feel more comfortable using alternative methods because of the additional non-lead validation steps that will now be required. Our experts advise that the validation step was likely added to address concerns with machine learning and other methods where you don’t physically see the wall of the pipe. The non-lead validation pool provides a second check on the service lines classified as “non-lead” by the end of 2034. Contact our team to learn more about how to set up your inventory for the non-lead validation pool.

"Any utility that has a significant number of unknowns in their service line inventory can take advantage of predictive modeling and we can work to help obtain state approval,” advises Trinnex data analyst Katie Deheer. Using machine learning enhances material classification, streamlines field verifications, and prioritizes program efforts to save utilities time and money. Katie’s team of data scientists has developed a predictive modeling tool called leadCAST Predict to help water systems meet LCRI requirements while protecting public health.

What is the impact if you have lead connectors and galvanized service laterals?

Lead connectors upstream of galvanized service lines are not considered GRR. However, they will be included in the new Tier 3 pool for sampling and need to be prioritized above copper with lead solder sites. As mentioned, lead connectors must be included in the baseline inventory.

Additionally, the LCRI requires that any lead connector be replaced when encountered through planned or unplanned work in the distribution system. The replacement and verification deadlines do not apply to connectors, and so lead and unknown connectors can remain in perpetuity. The EPA adjusted the definition of lead connector to be specifically 3-feet in length or less, and so if there is knowledge or documentation that lead goosenecks are longer, they must be treated as lead service lines. Systems should keep goosenecks on their radar as some states are regulating any lead goosenecks as lead service lines.

partial and private side replacements

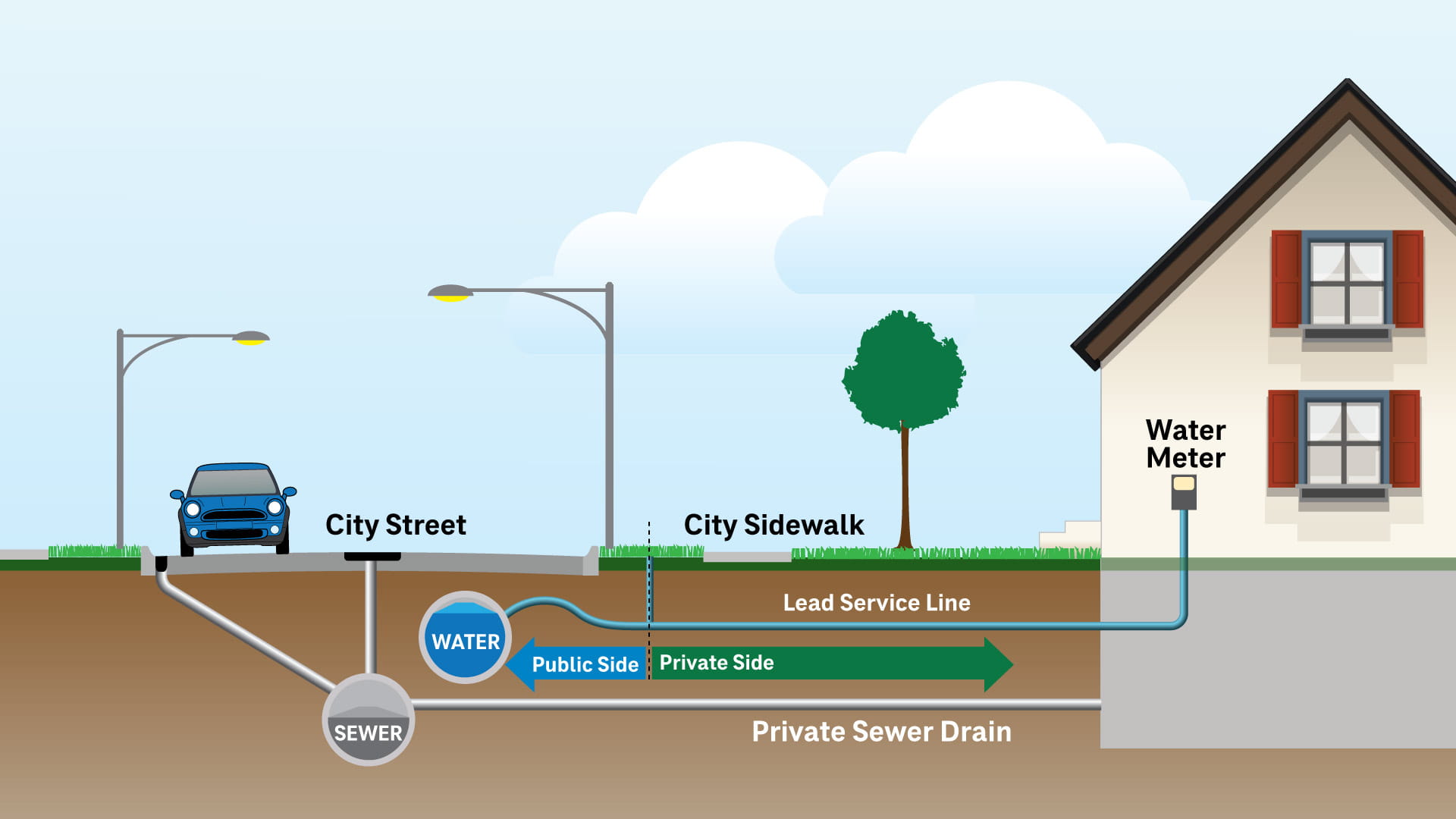

If the property owner denies consent for the replacement of the portion of the service line they own, can the utility replace the city side of the line?

The LCRI limits partial replacements to emergency situations and with planned capital improvement projects only. Emergency situations are when there is a leak or a break on a lead pipe on the utility side and the customer side is galvanized, lead or unknown. Within 45 days of the emergency event, the utility side must make four attempts to offer to replace the customer side of the line.

During a planned water main project or other capital improvement projects, the utility must offer to replace the customer’s side of the line in advance. After four attempted offers, if the customer will not consent, the utility can proceed with the planned work that results in a partial replacement. All of the post-partial replacement mitigation requirements must be followed per the Rule including flushing instructions, 6 months worth of filters and follow-up sampling that captures both the first liter and the service line (or 5th liter).

Partial replacements are not permitted to be conducted as part of a lead service line replacement program. If the customer does not consent after four attempts or if there are other legal restrictions preventing access or work on private property, the water system cannot replace the utility side of the lead service line. Both sides of the line must be left undisturbed. Water systems will need to track when that home is under new ownership, and start over the four attempts offering the replacement to the new homeowner.

If a partial replacement is completed, it will not count towards meeting the overall minimum replacement rate calculation. The service line remains a lead service line even if the customer refused replacement.

When the utility side is lead and the customer side is non-lead, and a meter located within the house is replaced, is this case still considered a major disturbance?

Yes, we believe it meets the intent of a major disturbance. Since the line is classified as a lead service line and the meter replacement cuts into it, the work described would be considered a major disturbance if the meter is upstream of the designated “building inlet” or delineation of the service line and premise plumbing.

How should a utility proceed with a replacement if the lead portion is on the private side or if the service line is 100% privately owned?

The LCRI indicates that regardless of ownership, if a system can be provided “access” (i.e. through an owner’s signing of a Right of Entry agreement or other legal authority), then it is responsible for replacing the service line. The system must offer to replace the line, but if replacements are not funded through grants or loans, the utility does not have to pay for the replacement and can charge the customer. Regardless of ownership, the line must be offered to be replaced.

Does the utility have to offer to replace the customer's side, or can they simply refer them to contact a certified plumber?

A utility will be responsible for demonstrating the minimum replacement rate per year is achieved. There will be a range of approaches, mechanisms and incentives that should be considered to meet the minimum targets. It is our team’s understanding that utilities must offer to hire the contractor and perform the replacement for the customer. If certified plumbers are pre-approved, they must offer to coordinate with the plumbers if this is the elected route for replacement and not leave it to the customer to coordinate. However, the utility is not required to be responsible for the cost of the replacement on the private side. Our experts are seeking further clarification from the EPA on other contracting options for utilities.

Are utilities that have split ownership of service lines subject to the 10-year replacement requirement?

Yes. No matter the ownership, if the utility can get access with owner approval, then it is required to be in the replacement pool.

sampling protocols

What are the changes for school and childcare testing requirements from the LCRR to the LCRI?

The main school and childcare sampling changes under the LCRI are to the timeline (now expected to begin in 2028) and to the waiver exemption process. The type of sampling that may be considered for a system’s waiver has been expanded to include any past sampling consistent with EPA 3T’s methods conducted from 2021 up to the compliance period of 2028. This includes sampling conducted through voluntary programs funded by EPA’s WIIN Grants.

The detailed requirements such as the minimum number of samples per facility, the minimum number of facilities sampled per year and the sampling methods generally remain the same under the LCRR and LCRI.

Are sampling waivers required on a school-by-school basis, or can utilities view school district replacements as a whole?

It depends on the state and in what context the sampling is performed. For example, if a water system is being proactive and wants to get ahead of the proposed requirements, the state would likely require documentation of every school and childcare facility that had sampling conducted and the date those samples were taken.

If there is a requirement for public schools to perform sampling, or if the public school system has its own program and data process for conducting it, then the utility could consider a more bulk process. In many cases, it will be down to the school level to provide that data to the state to check which locations have been sampled and which still need to be.

How will the LCR monitoring schedule be impacted, especially for systems that were on a reduced monitoring schedule?

All systems with lead or galvanized requiring replacement at the time of the baseline inventory submission, will return to standard monitoring for at least two sampling rounds starting in 2028. Any system without LSLs or GRRs, but whose most recent 90th percentile calculated prior to November 1, 2027 is above 10 pbb must also return to standard monitoring. Systems without any lead services, galvanized lines or unknowns and a 90th percentile below 10 pbb will have the ability to stay on reduced monitoring. Systems that will have LSLs/GRRs at the compliance deadline, but expect a low 90th percentile under the revised sample site tiering and methods, may consider conducting standard sampling early, on a voluntary basis, in order to achieve reduced sampling by the LCRI compliance date.

corrosion control treatment

Under prior regulations like the LCR, there was a provision that allowed utilities to develop their corrosion control programs based on successful neighboring system experience (“analogous” systems). Will this still be a provision in the LCRI?

It will be, but it will depend on the utility characteristics. Large and medium systems with lead or galvanized services will not be able to, and these systems must conduct their own pipe loop studies. For smaller systems without lead, analogous system examples can be proposed to the state for expedited approval.

There are many nuances in the regulations, and our goal is to help utilities understand and comply with the LCRI.